SUPPLIER

DAICHO inc.

PRODUCTION AREA

- 湖東・近江(Koto/Omi)

SPECIALTY

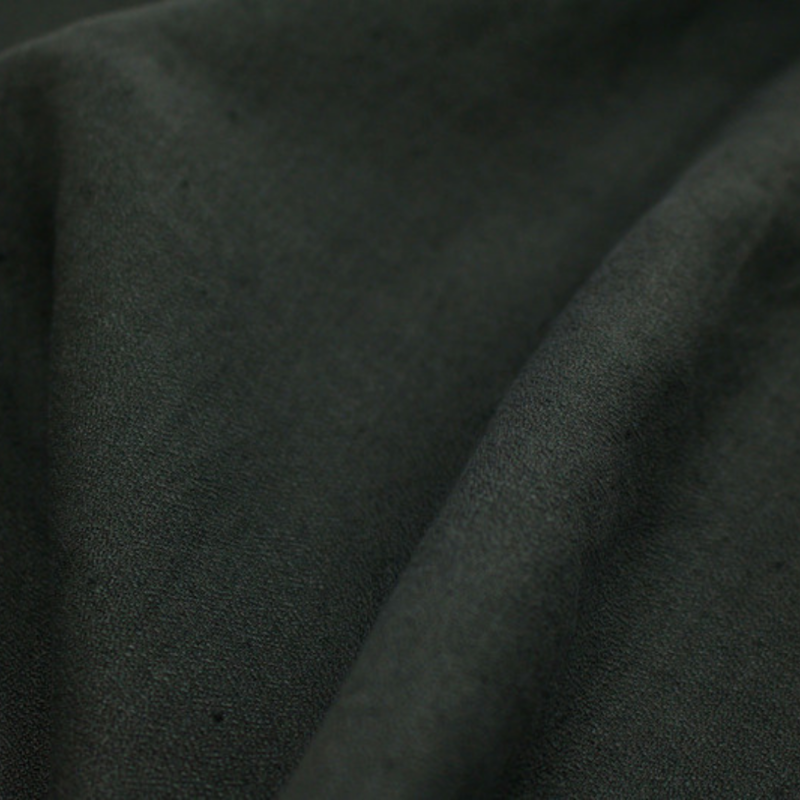

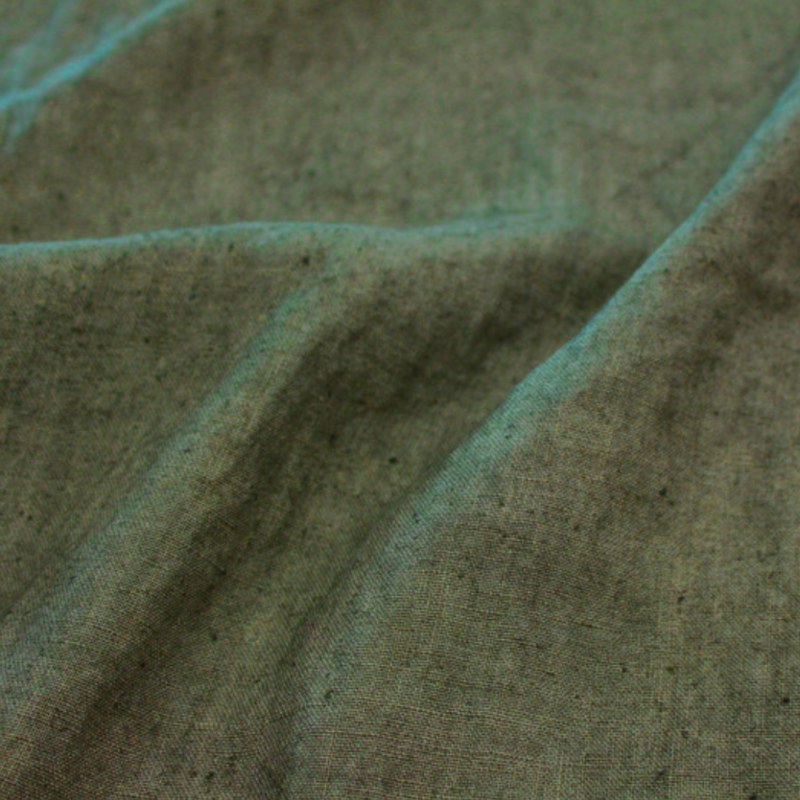

- Natural fiber, Linen , Interior

MINIMUM ORDER QUANTITY

- -

MINIMUM ORDER QUANTITY BY ORDER

- -

Story

Company Profile

| Company Name | DAICHO inc. |

|---|---|

| Production area | 湖東・近江(Koto/Omi) |

| Specialty | Natural fiber, Linen , Interior |

| Established | 1889 |

| Address Line1 | 611, Gokashoyanazecho-chou,omi-city, Shiga 5291413, Japan |

| Phone Number | +81748482574 |

| Manager | 山口直之 |

We started finishing of “Ohmi Johfu” in 1887.Beginning with bleach and dyeing of cotton, linen, silk, wool and synthetic fabrics, we are general textile processing mill for special texture, special shape finish, “Ohmi Chijimi”, processing kimono fabrics, bed fabrics and industrial fabrics. We believe that adding value to special Japanese materials rich in high quality leads to development of textile world. And we continue dispatch the materials to the world.